Busy week, Busy week.

So I spent the week picking at my fusebox tuck here and there.

The box has all of the wires I have removed, and all of the electric tape, and fuse/relay holders that were a part of the harness previously. And you can see where I have labeled the plugs by their names in the service manual.

Still have some relays left to dismantle and relocate.

Here is the new fusebox and me marking items off on the fsm.

This is my friday night, all of the relay and fusebox wiring is moved off to this side, and all of the wire ends I had to cut are thrown in that postal box so I can re-use them again if need be or just for reference purposes. I've been told a lot of wires are the same color but I have yet to run into that. I have located the actual turn signal plugs which I will have to run their wires back to the fusebox relay.

It was almost impossible to de-pin this plug, as much as I tried to get the retainer strip out of the center I could not. So I took the easy way out. The only setback this really causes is sleeving it. If I cant get the sleeving on from the plug end that means I will have to group all of those wires together and sleeve it from the back end, or just run sleeving wrap? (which will suck)

I've been removing some of the ignition related power items off a few of the junction plugs which I am sure at a later time may be a bad idea. But the wires were going to absolutely nothing. (factory) taped off and rolled up in the fusebox??? All of those wires have been removed and de-pinned or de-spliced separately.

That's what's left. Now to focus on our fusebox.

I'm pretty much all wired out, Saturday I took my flywheel to be re-surfaced and I picked up my nismo needle pilot bearing from west covina nissan. The machinist advised against re-using my pressure plate, but since I only plan on running this clutch for a little while only I guess I'll take my chances.

Now it's Sunday, it's about 4:40 in the afternoon.

Here is the a shot of the flywheel and the box filled with clutch components.

Here is our old pilot bearing...

And here I am removing all of the bolts and stuff from their respective homes. I would highly advise not to multi-task when putting an engine together and replacing a part of the car all in the same time frame... I will leave it up to you to see where I went wrong.

Pilot Bearing Removal from wayne edwards on Vimeo.

Bearing Breifing from wayne edwards on Vimeo.

Here is more dust from the old clutch disc, it just falls off of the pressure plate anytime it makes contact with anything, so I sat and tapped it on my driveway and wiped it down to remove some of the dirt and grime on it.

Here is the clutch all installed ready to put the transmission on... random shot of my engine harness just chillin, and to the right, our hard clutch line which we're replacing today.

bleeding the slave cylinder out.

all empty... There is some kind of goop in here at the bottom, I think once I get some fluid (and once I decide on what fluid i'm going to run and I'm open to suggestions." I am going to take that thing off and clean it.) The thing with the brake cylinder resivior and the clutch cylinder resiviour is you have to clean them with the fluid going in them.

It's wierd to explain!

My new line running across the engine bay, not as glamorous as some tucked lines, but I'm happier than a pig in shit. My clutch response is going to be so much better it's not even funny.

Taking these two nasties off... but what does the one running to the back of the car go to? hrmn??????

according to our friend mr.FSM you can unbolt pretty much everything i've colored red.

Here I am putting on the fitting end on the master cylinder itself, I bolted it to the transmission to remove the original rubber factory hose and fitting as I had no leverage with it dangling under the car.

It was kind of funny because I have a roomate who I cannot stand and parks like a dickhole in the middle of the driveway (owns the bmw) and I pressed the needle on my slave cylinder only to have clutch/brake fluid fly out of it onto his hood. LOL! I quickly wiped it off but knowing his dumb ass he wont notice any difference in his paint... Unless it peels off in the morning hahaha!

So anyway while i'm sitting here laughing it up I get the transmission installed. And right before I bolted it up I walked over and put the clutch slave cylinder up only to notice I left the godamned transmission sandwich plate in the goodie box, so I had to take the whole fucking thing apart again to get that one piece on... And to add more fustration to my already negative mood...

It started pouring it's ass off on top of my head. Man oh man I was fucking livid, everything got soaking wet. I have to hoist the engine back up in the air and then push it into the garage, then I had to tilt it back to get the water out of the spark well area. Then I had to wipe everything down and let it dry before I started the re-assembly, the rain calmed down so I resumed work and then it started up again. GODAMNIT!

I really wanted to get this thing in today!

Instead i'm wiping it down and re-assembling it which is going to take more time because i'm in the rain doing it. AAAAARG!!!

either way I got it assembled and that is pretty much the end of my workday in the garage.

Installing transmission from wayne edwards on Vimeo.

Now I just need to finish the fuse box so I can have my alarm installer come and work his magic.

To be continued

-Wayne-

The box has all of the wires I have removed, and all of the electric tape, and fuse/relay holders that were a part of the harness previously. And you can see where I have labeled the plugs by their names in the service manual.

Still have some relays left to dismantle and relocate.

Here is the new fusebox and me marking items off on the fsm.

This is my friday night, all of the relay and fusebox wiring is moved off to this side, and all of the wire ends I had to cut are thrown in that postal box so I can re-use them again if need be or just for reference purposes. I've been told a lot of wires are the same color but I have yet to run into that. I have located the actual turn signal plugs which I will have to run their wires back to the fusebox relay.

It was almost impossible to de-pin this plug, as much as I tried to get the retainer strip out of the center I could not. So I took the easy way out. The only setback this really causes is sleeving it. If I cant get the sleeving on from the plug end that means I will have to group all of those wires together and sleeve it from the back end, or just run sleeving wrap? (which will suck)

I've been removing some of the ignition related power items off a few of the junction plugs which I am sure at a later time may be a bad idea. But the wires were going to absolutely nothing. (factory) taped off and rolled up in the fusebox??? All of those wires have been removed and de-pinned or de-spliced separately.

That's what's left. Now to focus on our fusebox.

I'm pretty much all wired out, Saturday I took my flywheel to be re-surfaced and I picked up my nismo needle pilot bearing from west covina nissan. The machinist advised against re-using my pressure plate, but since I only plan on running this clutch for a little while only I guess I'll take my chances.

Now it's Sunday, it's about 4:40 in the afternoon.

Here is the a shot of the flywheel and the box filled with clutch components.

Here is our old pilot bearing...

And here I am removing all of the bolts and stuff from their respective homes. I would highly advise not to multi-task when putting an engine together and replacing a part of the car all in the same time frame... I will leave it up to you to see where I went wrong.

Pilot Bearing Removal from wayne edwards on Vimeo.

Bearing Breifing from wayne edwards on Vimeo.

Here is more dust from the old clutch disc, it just falls off of the pressure plate anytime it makes contact with anything, so I sat and tapped it on my driveway and wiped it down to remove some of the dirt and grime on it.

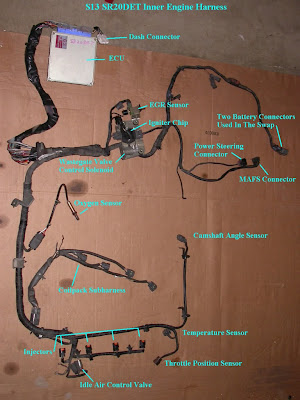

Here is the clutch all installed ready to put the transmission on... random shot of my engine harness just chillin, and to the right, our hard clutch line which we're replacing today.

bleeding the slave cylinder out.

all empty... There is some kind of goop in here at the bottom, I think once I get some fluid (and once I decide on what fluid i'm going to run and I'm open to suggestions." I am going to take that thing off and clean it.) The thing with the brake cylinder resivior and the clutch cylinder resiviour is you have to clean them with the fluid going in them.

It's wierd to explain!

My new line running across the engine bay, not as glamorous as some tucked lines, but I'm happier than a pig in shit. My clutch response is going to be so much better it's not even funny.

Taking these two nasties off... but what does the one running to the back of the car go to? hrmn??????

according to our friend mr.FSM you can unbolt pretty much everything i've colored red.

Here I am putting on the fitting end on the master cylinder itself, I bolted it to the transmission to remove the original rubber factory hose and fitting as I had no leverage with it dangling under the car.

It was kind of funny because I have a roomate who I cannot stand and parks like a dickhole in the middle of the driveway (owns the bmw) and I pressed the needle on my slave cylinder only to have clutch/brake fluid fly out of it onto his hood. LOL! I quickly wiped it off but knowing his dumb ass he wont notice any difference in his paint... Unless it peels off in the morning hahaha!

So anyway while i'm sitting here laughing it up I get the transmission installed. And right before I bolted it up I walked over and put the clutch slave cylinder up only to notice I left the godamned transmission sandwich plate in the goodie box, so I had to take the whole fucking thing apart again to get that one piece on... And to add more fustration to my already negative mood...

It started pouring it's ass off on top of my head. Man oh man I was fucking livid, everything got soaking wet. I have to hoist the engine back up in the air and then push it into the garage, then I had to tilt it back to get the water out of the spark well area. Then I had to wipe everything down and let it dry before I started the re-assembly, the rain calmed down so I resumed work and then it started up again. GODAMNIT!

I really wanted to get this thing in today!

Instead i'm wiping it down and re-assembling it which is going to take more time because i'm in the rain doing it. AAAAARG!!!

either way I got it assembled and that is pretty much the end of my workday in the garage.

Installing transmission from wayne edwards on Vimeo.

Now I just need to finish the fuse box so I can have my alarm installer come and work his magic.

To be continued

-Wayne-