5 hours of work... seriously

5 hours of work converting my ford Taurus fan connector over to a Nissan plug, then sleeving it... wanna see how and why?

Look no further.

Look no further.

I think I spent about an hour in front of the car de-pinning the relay all of the wiring was originally soldered to. I then decided to grab a bbq torch lighter and de-solder that way. Worked great, until I decided I wasn't going to use the relay anymore anyway, so I kind of wasted my time.

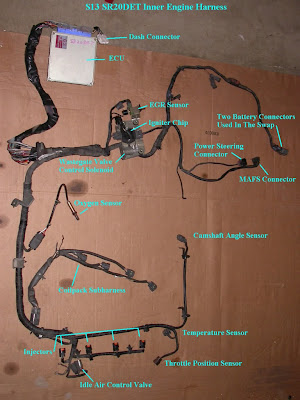

This was pulled from my s13 (Chloe) and worked just fine before, but the amperage draw of the fan was so high that the alternator couldn't provide enough power to run the fan nor could the system even take it running on high.

Some fun statistics for you.

1995 Ford Taurus (3.8L)

Dual speed

low: ~2500 cfm, Amp draw ~23.75A

Dual speed

low: ~2500 cfm, Amp draw ~23.75A

high: ~3800cfm, Amp draw ~46.5A

The problem with the fan going into high is the stock relays are all 40amp... So that could either burn out a fuse, cause a major accessory power draw (add up having your lights on, radio blasting, ac runing, etc.) Hell makes me want to upgrade my alternator now lol.

Anyway the point is you need stronger relays for the car if you're going to run this fan. I have decided to go with AEI component relays. you'll see on a drawing below the quantity i'm going to order (replacing ALL of my relays)

http://www.boardrelays.com/

----------------------------------------------

The instructions are as follows for this modification.

(all horrible spelling has been corrected. -137)

The control circuit shown is as follows..... When the temp. reaches your set low speed figure, let's say 190 deg.the low speed relay is energized through pin 86, 85 connects to 87A of the AUX relay and pulls 30 of that relay, 87 of the low speed relay and 30 are closed sending power to the fan to run at low speed.

ARE we confused yet?????

When the temp falls below the high speed switch figure the AUX relay will switch back to the low speed relay.

This set-up has worked great since installation of it and I fought heat problems for a year because of my blower set-up before this change and NO in dash switches.........

----------------------------------------------

Now the way he want's to wire it up is all fine and dandy, but I'm going with more traditional OEM wiring, I don't see where I will need all of these thermo's and what not. I have a nismo thermostat so that should actually put the car's natural cooling ability to use before I even need the electric fan to kick on. The DIF fan controller's look real nice but at 150, 200 dollars (which has integrated relays.) is just unecessary imo. More for the non Do It Yourselfer aka D.I.Y er lol.

Here is the OEM wiring charts for you to reference how i'm rolling. As mentioned above i'm replacing the stock relays with 60amp relays.

and here is the electric fan wiring layout, pay attention to the area I highlighted, now on my s13 (Chloe) this was all manually wired to the car, not integrated in an oem manner what so ever. So I'm going to use the oem fan plug from the Electric Fan

you can see here that there is a white/red wire in pin seat number 1 which goes to the fan relay #2 this is going to be our HIGH speed fan relay, the second wire is brown/white our LOW speed wire going to fan relay #1. Confused, ok i'll hold the actual plug itself i'm talking about.

I'll touch back later at how I am integrating that third (fail safe) relay into this oem setup.

So I have a power line for high, I have a power line for low, and look I even have dual grounds going to a stock location, so why wire the fan up separately when I can utilize this awesome plug?

Exaaaaaaactly...

let's get to work shall we?

Here is the Ford Taurus fan plug... the pinout goes like this.

1. blue (HIGH SPEED) 2. black/red (LOW SPEED) 3. black (GROUND)

I may not have them in that order but that's not important. - 137

I am using the plug from the stock electric fan which goes to the above pictured plug I don't remember the exact color pin out, nor can I find that in the maintenance manual. So fuck it, we're going to make our own pin out.

So lets start by taking the ground wire, extending it, and then splitting it into two so it can utilize not one, but two oem grounding points.

soldering.

done

So basically pins 3 (black) and 4 (yellow/green) on this plug will be going to pins 3 (black) and 4 (black) on E30.

now for the black/red wire, I've decided to use the green wire for low speed, this will be going into pin seat #1 on this plug.

The blue wire on the Taurus plug (pin #1) will go to the blue wire which we're going to put in pin seat #2 on the oem plug.

all of this heat shrink initially was a great idea until I had to figure out how in the hell to get the water proof grommet back onto the taurus plug, on top of the grommet cap. GODDAMMIT!

so I had to slice all of the heat shrink off, shimmy that crap on while widening some of the holes and filing down my crappy soldering.

here is all of the heat shrink re-applied now that the cap is where it's supposed to be.

(editors note: if you read this on a forum then came here and noticed this picture wasn't posted. is because I was not going back to every forum it wasn't posted on to repost it lol. - 137)

before I sleeve anything I group the wires in section and do a tight, and I mean TIGHT wrap of electric tape, probably two go arounds with the roll and cut. Moderately spaced which helps with the sleeve material I slide on.

finished product... but the project is far, from over.

The problem with the fan going into high is the stock relays are all 40amp... So that could either burn out a fuse, cause a major accessory power draw (add up having your lights on, radio blasting, ac runing, etc.) Hell makes me want to upgrade my alternator now lol.

Anyway the point is you need stronger relays for the car if you're going to run this fan. I have decided to go with AEI component relays. you'll see on a drawing below the quantity i'm going to order (replacing ALL of my relays)

http://www.boardrelays.com/

----------------------------------------------

The instructions are as follows for this modification.

(all horrible spelling has been corrected. -137)

The two diagrams above show how to build and wire an auto relay switched 2-speed FORD TAURUS fan. Parts needed......10 gauge wire for the power circuit. 18 gauge wire for the control circuit.

Three relays...

1) High speed relay, TYCO VF7-12V,70amps

2)Low speed relay and Aux relay, standard BOSCH relays

Two switches...

1)Low speed temp. switch- Adj. Flexilite, FLX-31147 from SUMMIT.

2)High speed temp. switch from Standard Motor Products, TS-158 or TS-392.

I put the adj. low speed switch and the three relays in separate relay boxes and mounted them in the engine comp. The high speed temp switch I mounted where one of the heater hoses went.

1) High speed relay, TYCO VF7-12V,70amps

2)Low speed relay and Aux relay, standard BOSCH relays

Two switches...

1)Low speed temp. switch- Adj. Flexilite, FLX-31147 from SUMMIT.

2)High speed temp. switch from Standard Motor Products, TS-158 or TS-392.

I put the adj. low speed switch and the three relays in separate relay boxes and mounted them in the engine comp. The high speed temp switch I mounted where one of the heater hoses went.

Est. cost of parts, less the fan, is $50.00 . 10 gauge wire is used in the power circuit and 18 gauge in the control circuit. The 12V switched control circuit can be connected to any live connection with ignition on.

The control circuit shown is as follows..... When the temp. reaches your set low speed figure, let's say 190 deg.the low speed relay is energized through pin 86, 85 connects to 87A of the AUX relay and pulls 30 of that relay, 87 of the low speed relay and 30 are closed sending power to the fan to run at low speed.

When the temp. reaches your high speed switch figure, let's say 210 deg. pin 86 of the AUX. relay energizes through 85 and 30 releases from 87A of the low speed relay and connects with 85 of the high speed relay which through 87 of that relay powers the fan to run at high speed.

ARE we confused yet?????

When the temp falls below the high speed switch figure the AUX relay will switch back to the low speed relay.

Therefore low and high speeds will never be on at the same time and you will have the following conditions...

1) No fan on.

2) Low speed on.

3) High speed on.

1) No fan on.

2) Low speed on.

3) High speed on.

This set-up has worked great since installation of it and I fought heat problems for a year because of my blower set-up before this change and NO in dash switches.........

----------------------------------------------

Now the way he want's to wire it up is all fine and dandy, but I'm going with more traditional OEM wiring, I don't see where I will need all of these thermo's and what not. I have a nismo thermostat so that should actually put the car's natural cooling ability to use before I even need the electric fan to kick on. The DIF fan controller's look real nice but at 150, 200 dollars (which has integrated relays.) is just unecessary imo. More for the non Do It Yourselfer aka D.I.Y er lol.

Here is the OEM wiring charts for you to reference how i'm rolling. As mentioned above i'm replacing the stock relays with 60amp relays.

and here is the electric fan wiring layout, pay attention to the area I highlighted, now on my s13 (Chloe) this was all manually wired to the car, not integrated in an oem manner what so ever. So I'm going to use the oem fan plug from the Electric Fan

you can see here that there is a white/red wire in pin seat number 1 which goes to the fan relay #2 this is going to be our HIGH speed fan relay, the second wire is brown/white our LOW speed wire going to fan relay #1. Confused, ok i'll hold the actual plug itself i'm talking about.

I'll touch back later at how I am integrating that third (fail safe) relay into this oem setup.

So I have a power line for high, I have a power line for low, and look I even have dual grounds going to a stock location, so why wire the fan up separately when I can utilize this awesome plug?

Exaaaaaaactly...

let's get to work shall we?

Here is the Ford Taurus fan plug... the pinout goes like this.

1. blue (HIGH SPEED) 2. black/red (LOW SPEED) 3. black (GROUND)

I may not have them in that order but that's not important. - 137

I am using the plug from the stock electric fan which goes to the above pictured plug I don't remember the exact color pin out, nor can I find that in the maintenance manual. So fuck it, we're going to make our own pin out.

So lets start by taking the ground wire, extending it, and then splitting it into two so it can utilize not one, but two oem grounding points.

soldering.

done

So basically pins 3 (black) and 4 (yellow/green) on this plug will be going to pins 3 (black) and 4 (black) on E30.

now for the black/red wire, I've decided to use the green wire for low speed, this will be going into pin seat #1 on this plug.

The blue wire on the Taurus plug (pin #1) will go to the blue wire which we're going to put in pin seat #2 on the oem plug.

all of this heat shrink initially was a great idea until I had to figure out how in the hell to get the water proof grommet back onto the taurus plug, on top of the grommet cap. GODDAMMIT!

so I had to slice all of the heat shrink off, shimmy that crap on while widening some of the holes and filing down my crappy soldering.

here is all of the heat shrink re-applied now that the cap is where it's supposed to be.

(editors note: if you read this on a forum then came here and noticed this picture wasn't posted. is because I was not going back to every forum it wasn't posted on to repost it lol. - 137)

before I sleeve anything I group the wires in section and do a tight, and I mean TIGHT wrap of electric tape, probably two go arounds with the roll and cut. Moderately spaced which helps with the sleeve material I slide on.

finished product... but the project is far, from over.